The Journey from Pencil Sketch to Fireproof Enamel Mug

Here's a look into the steps involved in making our hand-drawn wildlife enamel mugs:

1. Inspiration, thumbnail sketches, and sizing

After gathering inspirational photos (since drawing bears in the wild is complicated), I create a few loose pencil thumbnail sketches. I've learned from experience that it's important to know the dimensions of the final product before starting. In this case, the designs are very horizontal so the wildlife scenes cover the full width of the mugs.

2. Ink drawings and color separations

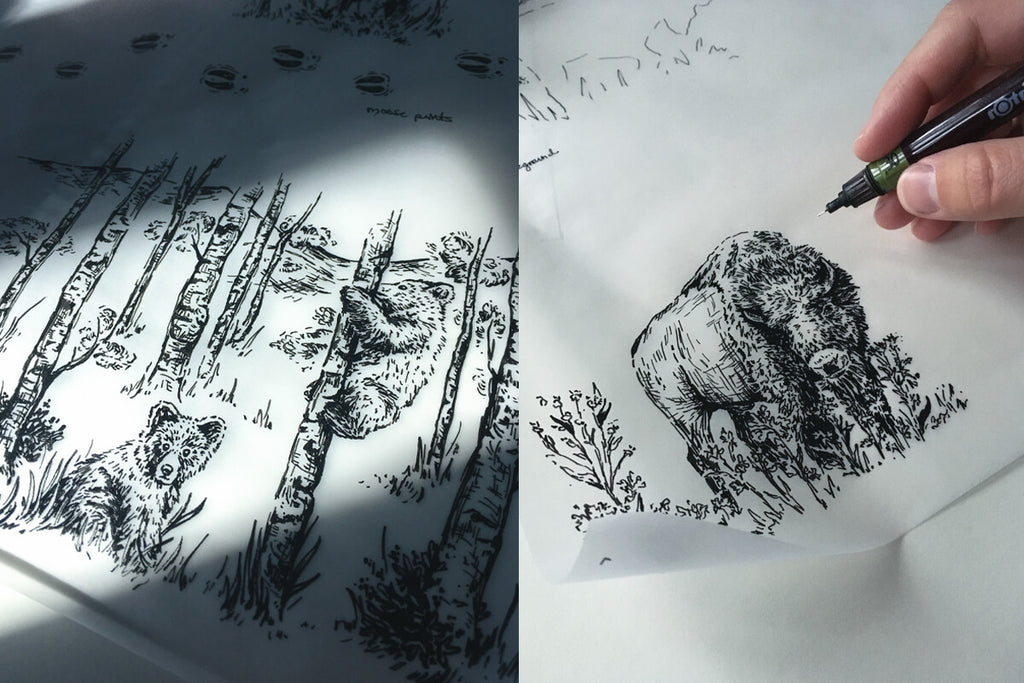

I jump directly from pencil thumbnails to ink drawings on tracing paper (I find that inking on top of completed pencil drawings feels stodgy and loses the organic lines that occur when I draw naturally).

When manufactured, each wraparound design uses three separate ceramic decals (one per color). So I separate each "layer" of artwork by color. I use tracing paper because it allows me to see how the layers line up as I go.

I used the bear drawing above to get a feel for the density of the final ink layouts and recreated each element separately later.

3. Scan and digitize

After scanning each element of the final drawings, I digitize them and clean up any elements that don't line up.

My concept for these designs began as the Four Seasons of American Wildlife. I love the winter elk design, but received feedback that the national park these were originally intended for is closed in the winter. I ended up using the winter scene on our Seasonal Wildlife Bandana and created a new landscape for the elk mug.

4. Manufacturing

I send the artwork to be transformed into what are considered the highest quality enamel mugs in the world. Enamel mugs are our only non-USA made product because 1) American manufacturing isn't available, and 2) we are proud to support an ethical family business with more than 100 years of experience (plus, Poland invented enamelware!)

- After the proofing process is complete, a mug starts as a piece of sheet metal that is cut, formed, and welded.

- Next, the steel is coated with an enamel base coat, inspected, fired, and inspected again.

- The mug goes on to be coated with an inside color, outside color, and hand dipped in extra robust enamel to create the rim and handle accents (with inspections, firing, and drying between each layer).

- Finally, ceramic decals (of the design) are applied by hand, dried, fired, and inspected (yes, again!)

- The final mugs are durable, fireproof, and made to last a lifetime.

The baby bison is my favorite.

5. Ship to you!

Finally, the mugs travel across the ocean, through customs, and I photograph and list them for sale.

The journey from pencil sketch to finished enamel mug takes 4-5 months. But the best part is shipping them to YOU... where they become part of your adventures!

Shop Wildlife Enamel Mugs. Share your mug's adventures by tagging #MyAlpinecho!

Leave a comment